There is more than one way to skin an onion and this take on film processing is a good example. Kodak's HC-110 is a very versatile liquid developer that gives excellent results with many films and is known for long shelf life. It works well in small tanks and in rotary systems. It was my standard developer for many years and although I no longer use it regularly I still recommend it to anyone looking for a good all-rounder.

The approach described below is one where different contrast ranges are achieved by using developer dilution as the variable, instead of the usual change in time. Here time, temperature and agitation are kept at a constant. I didn't create this but I have used this myself, probably because I enjoy the way it gets me thinking about film development controls in a new way.

What follows is transcribed from The Handbook for Contemporary Photography, 4th Edition by Arnold Gassan. 1977. Arnold was a professor of mine at Ohio University and I don't think he would mind me sharing this. I think it interesting and still useful.

Contrast Control through Developer Dilution

Another way of controlling contrast...is through varying the dilution of the developer. This is a very useful control with some of the liquid concentrate stock solutions, and of these Kodak HC-110 developer offers exceptional qualities.

Contrast control through developer dilution uses the high energy HC-110 with its almost unique ability to provide very clean separations of shadow densities and also offer linear separations of all equal exposures into the high densities, even though diluted to a very great degree.

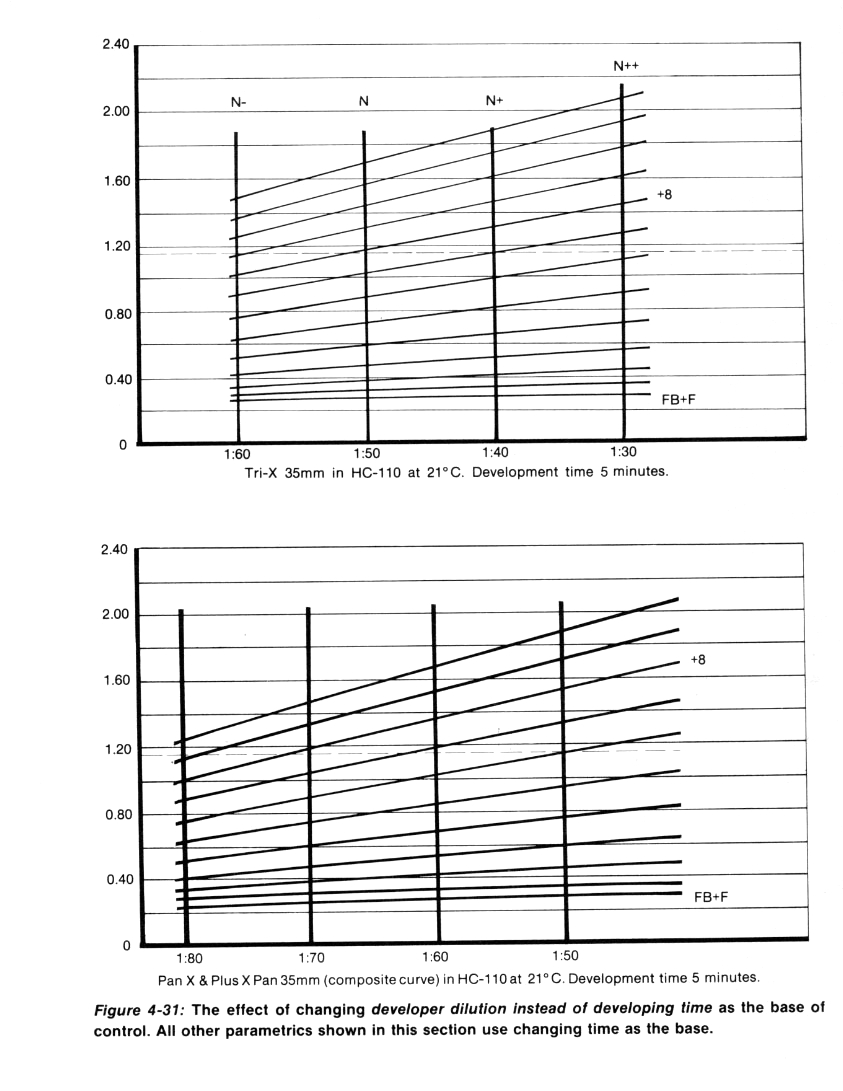

The effects of varying developer dilution for HC-110 and Tri-X rather than developing time can be seen by examining figure 4-31.

These curves show the equal separation in the shadows and also the contrast variations possible by merely varying the concentration of the HC-110 while keeping time, temperature and agitation constant.

The advantage of this system is that a widely distributed, very stable, highly concentrated commercially available developer of known quality is used only at a standard time-- one which is physically long enough to avoid problems inherent in short developing time. The concentrated syrup can be measured accurately with pipettes, or this simple two step dilution schedule can be employed:

Make a working stock of 1 part developer and 9 parts water.

Do not mix more than what will be used in a few days.

Distilled water is recommended.

From there dilute the working stock in dilutions as follows to make dilutions of approximately:

*Total=450 ml for a two reel tank.

In my own approach to HC-110 I have always skipped the stock solution step and mixed my developer directly from the syrup. I also abandon Kodak's letter system (dilution A, B, C etc) and use a ratio that is easy for me to remember and to mix. I used that with this system and when I use HC-110 in the more conventional way.

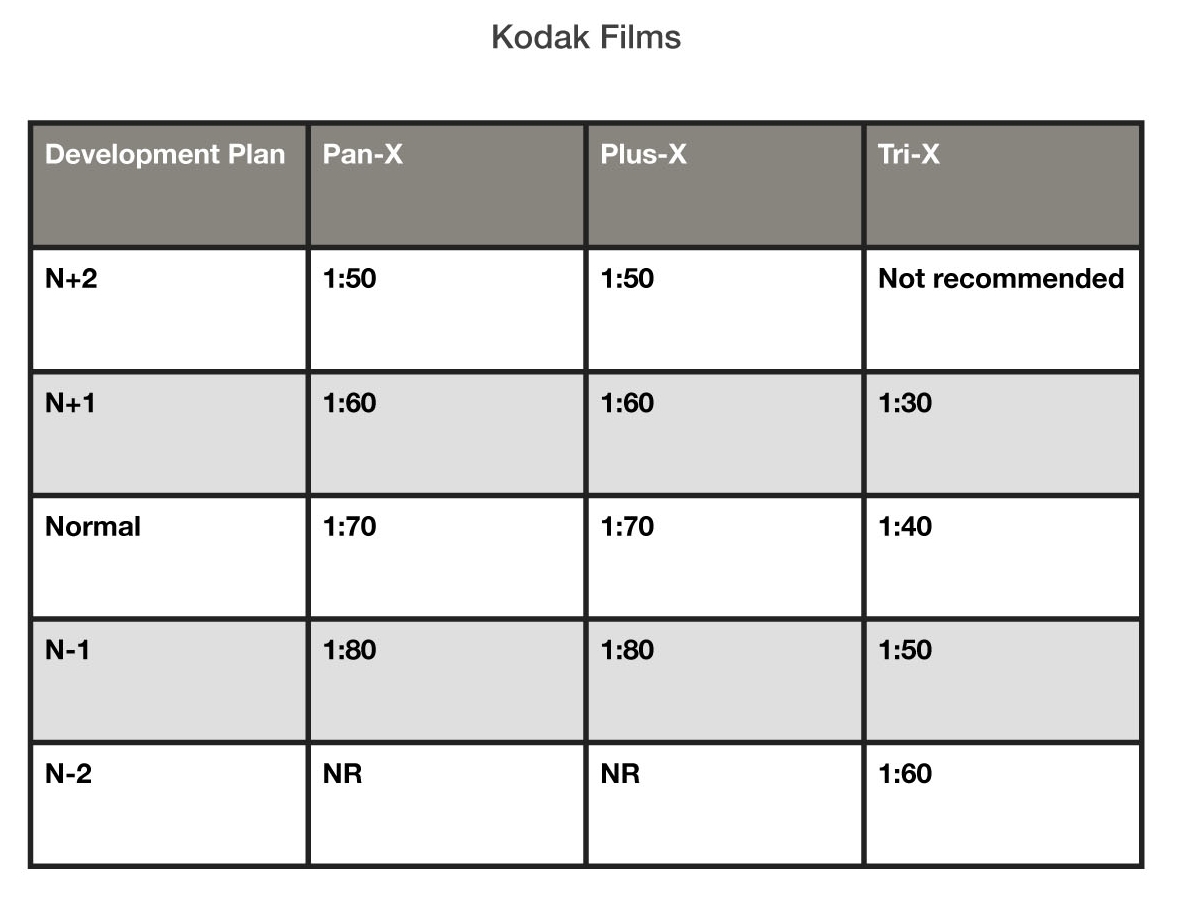

Gassan provides some recommended dilutions for a variety of films, but keep in mind a few things:

- These dilutions are from the 1:9 stock solution to approximate dilutions from the syrup (ratios in the left hand column).

- This data is from 1977 and films have changed

- He finds that a "decade change of dilution e.g. a change of 1:50 to 1:60 approximates a paper contrast grade". (for Kodak films, see below)

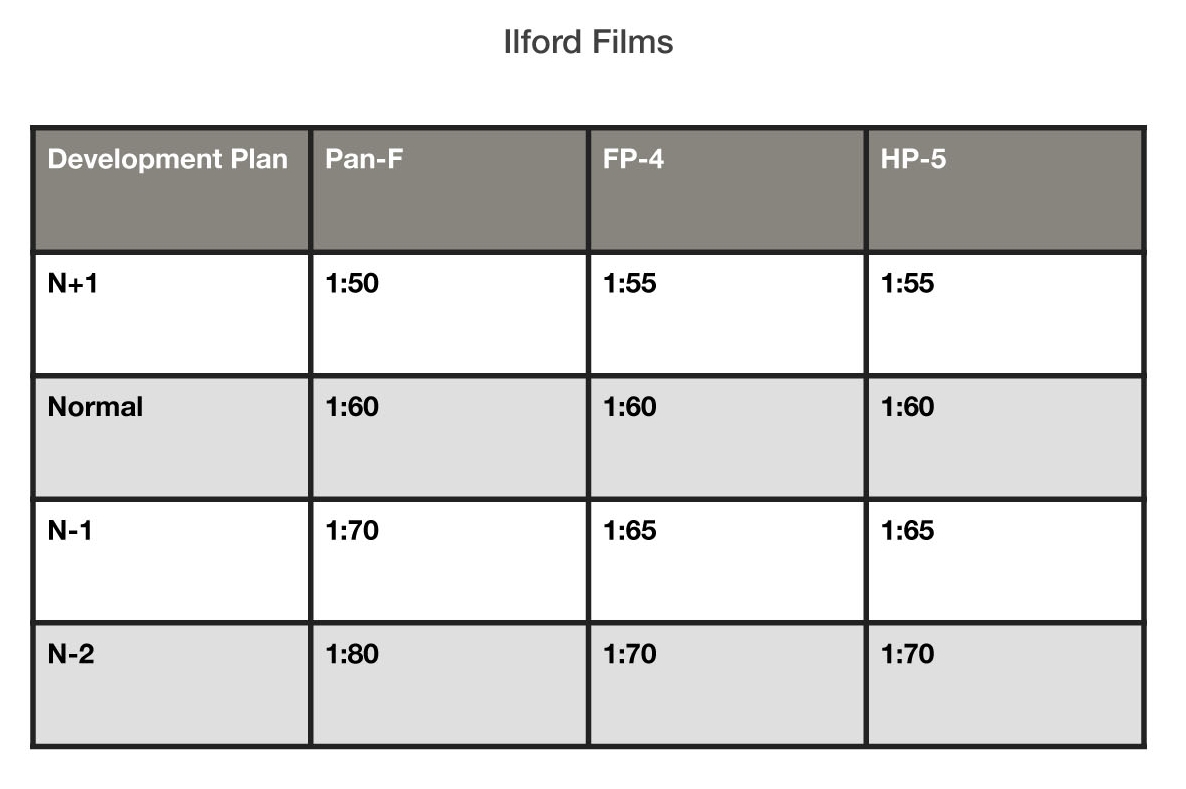

- The system works for Ilford films as well, but that they exhibit greater sensitivity to developer strength variations.

- There is almost no loss of shadow detail with this developer, even at the extreme dilutions.

All film is developed in HC-110 at 21C / 70F for five minutes with standard agitation.

"N" meaning Normal contrast in zone system terminology

Gassan based these dilutions on a goal of developing a highlight density [zone VIII], to a density of 1.15 above FB+F.

He concludes with this insight into his approach to 35mm photography:

The whole purpose of this control system is to produce high quality, low density negatives that will print easily and well, rather than to "push" film. High energy developers produce high densities under extreme low light levels. And they also produce negatives that are more graphic and less tonal -- that are not so much translations of colors into the grey scale of the photographs as they are graphic simplifications of the world.

The sense of graininess in 35mm is affected by exposure far more than most photogaphers are willing to admit. A correctly exposed minimum density negative is "filmy"; this means that the page of a book can be read easily while looking trough the negative. The least overexposure will mar otherwise excellent negatives that would enlarge well and have maximum resolution of detail. Two stops overexposure will enlarge the grain so much that the maximum degree of enlargement with out obvious grain is about 6 diameters.

I've no doubt that many of his former students remember him saying "make a negative that prints easily and well..."

I've used this system myself and found that it worked quite well with Ilford HP-5. My "normal" was 1:55 for 5 minutes at 70˚F. That was over 20 years ago, so please take that, and all of this as starting point for your own testing.